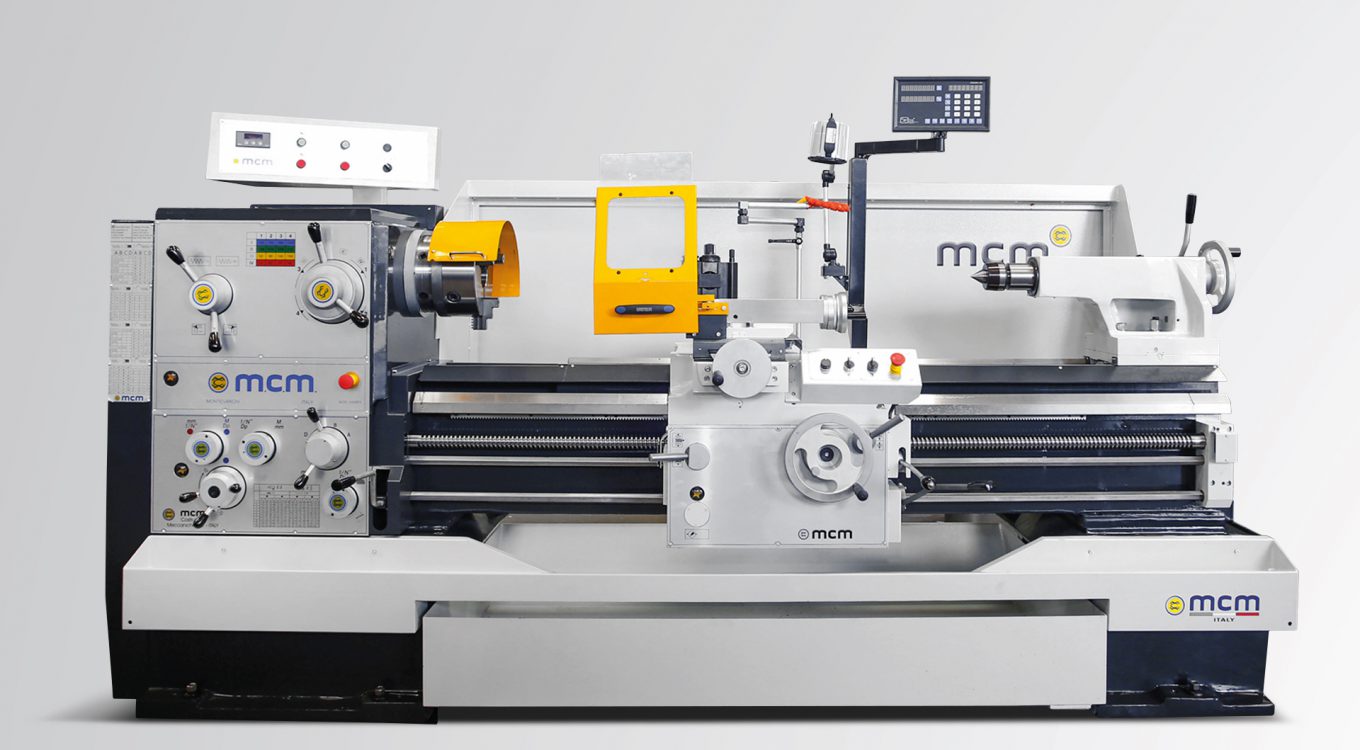

HANDY

250 - 280 - 330 - 360

- Protected Longitudinal Guideways

- Natural Gap

| Technical Specifications | 250 | 280 | 330 | 360 | |

|---|---|---|---|---|---|

| Height of centres | mm | 250 | 280 | 330 | 360 |

| Swing over bed | mm | 500 | 560 | 660 | 720 |

| Swing over cross slide | mm | 310 | 370 | 470 | 530 |

| Swing in gap | mm | 680 | 740 | 840 | 900 |

| Distance between centers | mm | 1500 - 2200 - 3000 | |||

| Bed width | mm | 400 | |||

| Spindle bore | mm | 80 | 102 | ||

| Spindle nose | Camlock | 8" | |||

| Number of spindle speeds | N. | 16 | |||

| Spindle speed range | rpm | 18:1500 | 15:1260 | ||

| Main motor power | Kw | 7.5 (9.2) | 9.2 (11) | ||

| Range of longitudinal feeds | mm/rev | (160) 0.05 - 11.52 | |||

| Range of transversal feeds | mm/rev | (160) 0.025 - 5.76 | |||

| Range of threads Metric | mm | (62) 0.05 - 112 | |||

| Range of threads Whitworth | T.P.I. | (80) 1/4 - 56 | |||

| Range of threads Module | mm | (54) 0.25 - 56 | |||

| Range of threads Diametral Pitch | DP | (80) 1/2 - 112 | |||

| Cross slide travel | mm | 360 | |||

| Top slide travel | mm | 150 | |||

| Tailstock quill diameter | mm | 80 | |||

| Tailstock quill travel | mm | 230 | |||

| Tailstock quill taper | Morse | 5 | |||

| Weigth | 250 | 280 | 330 | 360 | |

|---|---|---|---|---|---|

| HANDY x 1500 | Kg | 3400 | 3500 | 3700 | 3900 |

| HANDY x 2200 | Kg | 3800 | 3900 | 4100 | 4300 |

| HANDY x 3000 | Kg | 4600 | 4700 | 4900 | 5100 |

| Optional | ||

|---|---|---|

| Lathe with height of centres | mm | 400 |

Standard equipment

- Protected longitudinal guideways

- Natural gap

- Double mechanical clutch

- Electromagnetic brake

- Rapid feeds

- Bed – Legs – Headstock – Tailstock – Carriages made of cast iron

- Bed guideways are induction hardened and ground

- Headstock with induction hardened and ground gears; spindle is assembled on high accuracy bearings

- Carriages are sliding on antifriction material

- Air device on the tailstock to ease the displacement along bed

- Electric plant with low voltage control panel; it is placed in a suitable airtight cabinet.Make of components is Siemens and/or Schneider

- Spindle reduction sleeve

- 2 Dead centres

- Safety protections according to EC standards: plexiglas safety chuck guard with microswitch – turret plexiglas safety guard – rear protection along full length of the machine – protection of leadscrew and feed bars – emergency mushroom button

- Chip tank on wheels

- Cooling system with electro-pump

- Central lubrication of guideways with automatic pump

- Steady rest and follow rest

- Service tools and wrenches – Test certificate – Full electric diagram – Operation and maintenance book – Machine built according EC standards

Optional equipment

- Manual tool holder turret: Squared (4-way tool post) – Quick change turret – Indexing turret – Multifix turret

- 3 or 4 jaw self centering chuck

- 4-jaw independent chuck

- Live centre

- 2 or 3 axis digital readout

- Steady rest with larger Ø than standard one

- 6 position longitudinal stop

- Thread chasing dial

- Work area lighting

- Variable spindle speeds (Inverter)

- Cutting Surface Speed

- Powered small tool post

- Powered displacement of tailstock along bed

- Taper turning attachment

- Grinding equipment

- Levelling and anchoring pads

Would you like a quotation or more information for HANDY

Fill out the form, we will reply as soon as possible